Raw materials for producing insulating and shape molding products.

Go to products:

Sunde Group laid the foundation for a whole industry when it developed EPS technology – the process by which styrene is converted into polystyrene.

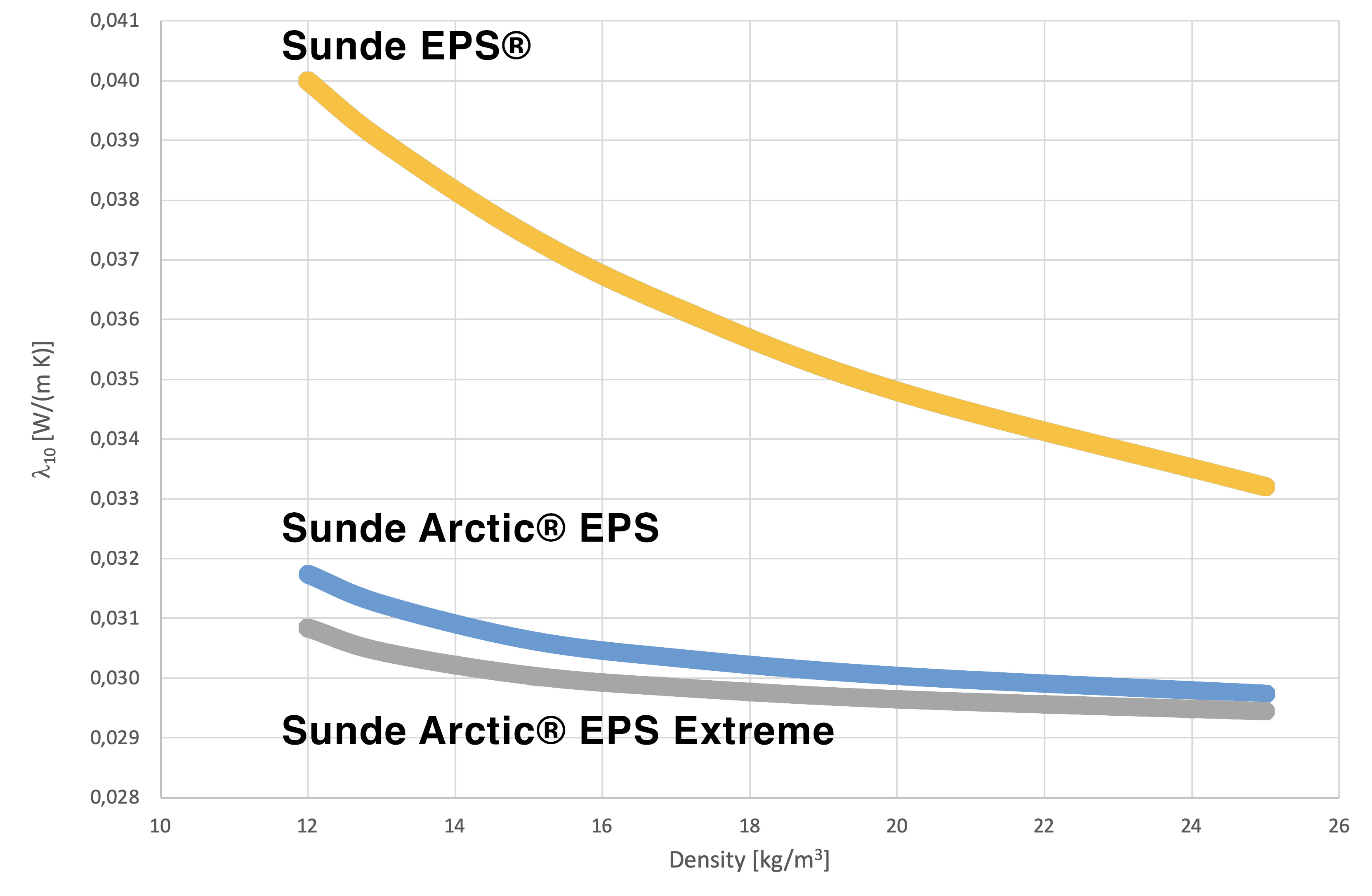

We currently offer two variants: Sunde Arctic EPS® and Sunde EPS®. The difference between the two is that Sunde Arctic EPS® has a 20% improved lambda value.

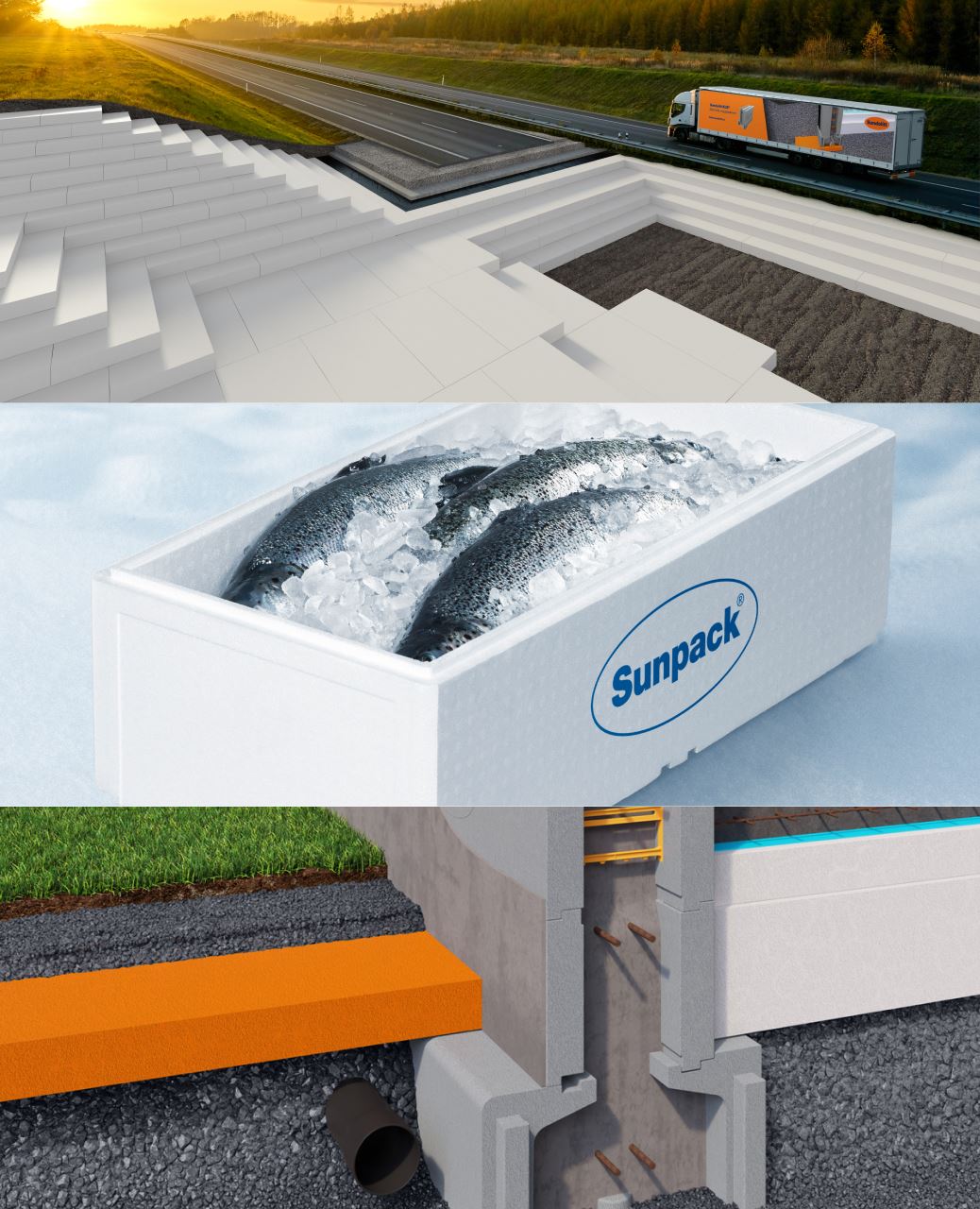

Sunde Arctic EPS® and Sunde EPS® are our raw materials used in the production of insulation products for building and construction, frost protection, road embankments, food packaging, technical packaging and other markets.

Only 2% raw material

Sunde Arctic EPS® and Sunde EPS® form the basis for finished products that contain only 2% polystyrene substance. This ensures a high insulation value, which in turn enables low energy consumption.

100% recyclable

Sunde Arctic EPS® and Sunde EPS® are 100% recyclable, and can be recycled an infinite number of times.

All Sunde Arctic EPS® products are also offered as Sundolitt 2nd Life™

Our raw materials have properties that contribute to less transport, less raw material consumption and a reduction in carbon emissions. In addition, the raw materials are 100% recyclable.

Sundolitt 2nd Life™ is all about recovering an ever-greater proportion of used packaging and insulation and recycling it into new raw materials. Recycling and reuse form one of the most important pillars of our climate strategy Sunde Balance™.

Sundolitt 2nd Life™

Sundolitt White to Grey™ is our concept for converting from white to grey EPS. The objective is to ensure even greener production and more environmentally friendly insulation products. Sundolitt White to Grey™ is part of our overall climate strategy Sunde Balance™. Sunde Arctic EPS® has a 20% improved lambda value compared to standard EPS.

Read more

Through our 2nd Life concept, we facilitate the collection of used polystyrene products. These are recovered and used in the production of new products. Through the mass balance approach*, we can document that the product's recycling rate corresponds to the amount of recycled material.

*Mass balance is a set of rules for determining the use of recycled content in a final product when both recycled and new raw materials are used in the process. Example: Sunde Arctic 2nd Life 30-284 contains 30% recycled polystyrene.

Sunde Arctic 284Block moulding

|

|

Sunde Arctic 284 ExtremeBlock moulding

|

|

Sunde Arctic 284 SEBlock moulding

|

|

Sunde Arctic 384Shape/block moulding

|

|

Sunde Arctic 2nd Life 30-284Block moulding

|

|

Sunde Arctic 2nd Life 30-284 SEBlock moulding

|

|

Sunde 121 StandardStandard block moulding, low density.

|

|

Sunde 123 StandardStandard block moulding, low density.

|

|

Sunde 223 standardBlock moulding, low density. Civil engineering application.

|

|

Sunde 224 standardBlock moulding, high density.

|

|

Sunde 322 standardShape moulding, fish-boxes, standard block moulding.

|

|

Sunde 151 SESE block moulding, low density.

|

|

Sunde 253 SE

SE block moulding, medium density.

|

|

Sunde 352 SESE shape-/block moulding. Wall thickness >10 mm. High density.

|

|

Sunde 2nd Life 30-223 standardBlock moulding, low density. Civil engineering application.

|

|

Sunde 2nd Life 30-224 standardBlock moulding, high density.

|

|

Sunde 2nd Life 30-322 standardShape moulding, fish-boxes, standard block moulding.

|

|

Sunde 2nd Life 30-151 SESE block moulding, low density.

|

|

Sunde 2nd Life 30-253 SE

SE block moulding, medium density.

|

|

Sunde 2nd Life 30-352 SESE shape-/block moulding. Wall thickness >10 mm. High density.

|

|